Skip to Main Content | 310-970-0007 | [email protected]

Skip to Main Content | 310-970-0007 | [email protected]

What is CIPP?

What is CIPP (Cured-In-Place-Pipe)? How Does It Transform Pipe Rehabilitation?

CIPP, or Cured-In-Place-Pipe, is a revolutionary trenchless plumbing technique used to rehabilitate and restore existing pipelines without the need for extensive excavation.

Whether you’re a contractor, property manager, or homeowner, understanding CIPP can be crucial for maintaining and upgrading your piping systems with minimal disruption.

Let’s dive into what CIPP is, how it works, and why it’s a game-changer in modern plumbing solutions.

How Does CIPP Work?

The CIPP process involves several key steps:

1. Inspection and Preparation

Before applying CIPP liner, the existing pipe is inspected using a camera to assess its condition.

The pipe will need to be cleaned and descaled to remove any obstructions in preparation for the liner installation.

2. Inversion or Pull-Through

A resin-saturated liner is inserted into the existing pipe.

This liner is either inverted (pushed through using an extruder inversion drum) or pulled through the pipe, depending on the specific method used.

3. Curing

Once the liner is in place, it is cured depending on the resin that was used. The curing process hardens the resin, forming a new, durable pipe within the old one.

Some resins require heat or steam to speed up the curing process, while Sewertronics offers UV light curing solutions.

4. Inspection and Reinstatement

After curing, the new CIPP liner is inspected to ensure it meets quality standards.

If needed, a robotic a robotic cutting device will be inserted into the newly lined pipe to reinstate any branch line connections. The pipe is then put back into service.

What Are the Benefits of CIPP Rehabilitation?

Minimal Disruption

CIPP requires no excavation, significantly reducing disruption to landscaping and existing structures, making it ideal for urban and residential areas.

Cost-Effective

By eliminating the need for excavation and minimizing surface restoration, CIPP often proves to be more cost-effective than traditional pipe replacement methods.

Durable and Long-Lasting

The cured-in-place liner is highly resistant to corrosion, leaks, and other common pipe issues, providing a long-lasting solution with an extended lifespan.

Fast Installation

The trenchless CIPP process is much quicker compared to traditional methods, reducing downtime and inconvenience.

Versatility

CIPP can be applied to various types of pipes, including those made of clay, concrete, or PVC, making it a versatile solution for different plumbing systems.

Ready to go Trenchless?

Try out our CIPP Payoff Calculator to select your extruder and calculate how fast your investment will pay for itself!

Our CIPP Supplies

RotoMidi and RotoMax

These high-tech milling machine's from Boldan are designed to efficiently clean pipes, removing roots, concrete, failed gaskets, and other pipe imperfections.

Engineered with safety and efficiency in mind, they can work with a comprehensive range of tools suitable for sewer renovation.

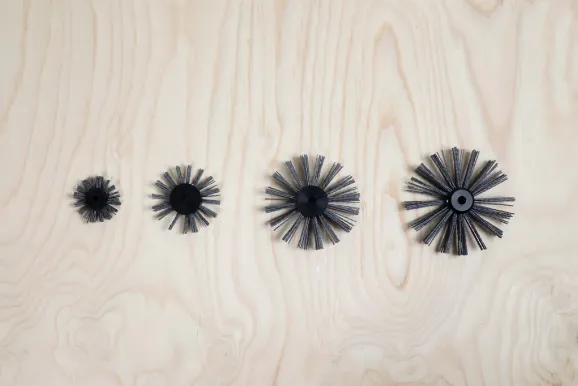

Cleaning Brushes

Carbide cleaning brush for removing fine dust or light mineral deposits in PVC and fragile pipes. Also used for brush coating pipe preparation.

Nylon cleaning brushes for the Mini and Midi Cleaners. Custom designed, high-quality and long-lasting brush use for coating and cleaning PVC pipes.

Ready to learn more?

Send us your information using the form below and we'll reach out to answer any questions you may have and help you select the best trenchless supplies for your needs.

536 HAJOCA CORP COMPTON

1220 W WALNUT STREET

COMPTON, CA 90220-5010

Master Distributor of Trenchless Supplies

310-970-0007

© Copyright 2024 Hajoca Corporation | All Rights Reserved | Privacy Policy | Accessibility Statement